Cellulose Nanomaterial – Advanced Material 1

This post is part of the Advanced material series. I will try and cover 10 such materials over the course of time. Some materials might be covered across 2 newsletters.

Reading time: 12 minutes, Words: 2600

Introduction: The success of human civilization throughout history has hinged on its ability to manipulate and utilize the materials found on our planet. Each new material provided advantages that gave early cultures the ability to survive the elements, conquer nature, vanquish their enemies, and build a better life.

Now, our focus has switched to devising and manufacturing whole new materials, some with the potential to transform our world again.

TLDR

Nanocellulose materials are advanced green materials extracted from Cellulose. Cellulose is abundantly present as part of plant cells. Nanocellulose is extremely versatile due to its superior mechanical properties, adaptable surface chemistry, low cost, easy extraction, etc.

Recent developments in engineering, biomaterials, and other high-end applications demonstrate the importance and capability of different celluloses, especially nanocellulose. These materials have been frequently used in water purification, medical services, and veterinary medication.1 Apart from these already implemented applications, nanocellulose is being explored in multiple use cases such as tissue engineering, cements, supercapacitors, batteries, cements, 3D printing, food additives, clothing etc.

Despite cellulose having been widely studied for several decades, nanocellulose has emerged as a prominent and outstanding material in the last two decades, as indicated by three widely employed databases, namely Web of Science, PubMed, and ProQuest (Bacakova et al., 2019).

The current overall market size is small at $300 Mn & expected to reach $1 Bn, growing at 20% CAGR, by 2027.

However, in my opinion the total market size will be far higher as:

Proof of science behind applications such as bioimplants, adhesives, etc increases

Awareness about green materials gains momentum

Largescale industries such as oil and cement find more applications

What’s covered in this article

Brief Context

What is nanocellulose material?

What is so special about this material?

Where can we use these materials?

How does it get manufactured? Easy or Tough?

Is the market big and has anyone used it yet? Few companies in this industry

Conclusion

Context:

Nowadays, the application of green, renewable and sustainable materials has become increasingly important for producing various high-value products with low environmental impact. This area of research has attracted the interest of a great number of academicians and industrials as such materials turn out to be an alternative solution to the ever-depleting non-renewable sources, environmental pollution, global warming, and energy crisis. In this context, cellulose, starch, alginate, chitin, chitosan, and gelatin have been revealed to be promising candidates with regards to their abundant availability from various resources. Among them, cellulose is by far the most abundant renewable compound obtained from the biosphere and it can be found in plants, algae, tunicates, and some bacteria.2

Its annual production is estimated to be between 10^10 and 10^11 t, but only a small portion of 6 × 10^9 t is exploited by a number of industrial fields such as papers, textile, chemical, and material industries

What is Cellulose Nanomaterial?

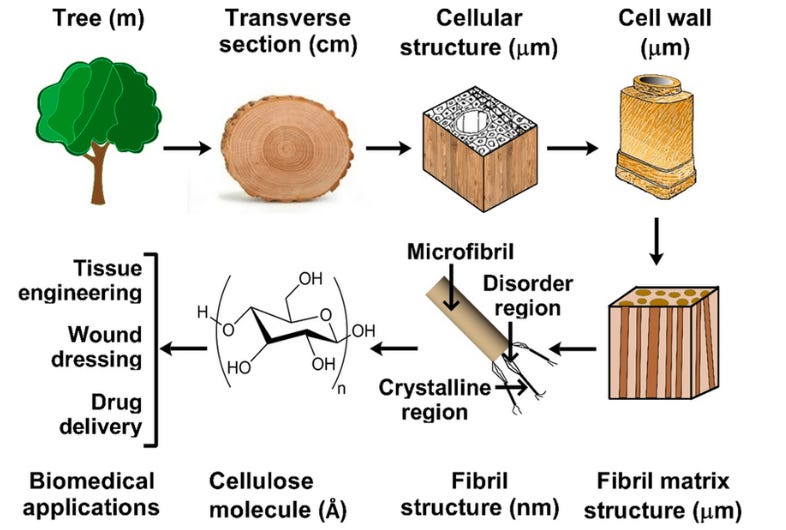

Cellulose nanomaterial as the name suggests, are nanomaterials derived from cellulose. These are the small building blocks of plant cellulose, which are now extractable easily. These can be Cellulose Nanocrystals (CNCs), Cellulose Nanofibers (CNFs) or Bacterial Nanocellulose (BCs) . Nanoscale materials have a size of about 100 nm in at least one dimension and have specific physicochemical, optical, magnetic, and biological features compared to the bulk materials.

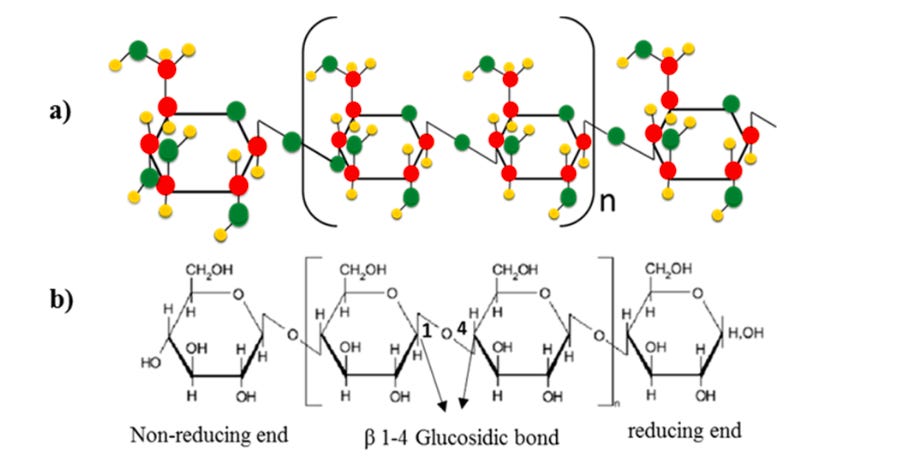

So what is Cellulose? - Simply stated, cellulose is a molecule, consisting of hundreds – and sometimes even thousands – of carbon, hydrogen and oxygen atoms. which appears like this:

Pic Source: Researchgate

Cellulose is the main substance in the walls of plant cells, helping plants to remain stiff and upright. Humans cannot digest cellulose, but it is important in the diet as fiber. “Cellulose is an insoluble substance which is the main constituent of plant cell walls and of vegetable fibers such as cotton. It is a polysaccharide consisting of chains of glucose monomers”3

So what is so special about Nanocellulose?

Its ‘Versatility’

And it is versatile because it is/has:

Abundantly available and hence low cost

Biodegradable and sustainable

Excellent mechanical properties - high surface area-to-volume ratio, high Young's modulus, high tensile strength, low coefficient of thermal expansion

Biocompatible & low in cytotoxicity

Inherent compatibility with organic polymer (adaptable surface chemistry)

Optical transparency

Where can we use these materials?

Nanocellulose, which can currently be produced on an industrial scale (10^11 tons annually), can be employed in several fields in our lives. I have listed four applications in slight detail and the rest just as headings. Each application is an area of research in itself, with technical and manufacturing nuances.

Biomedical products - Due to Nanocellulose’s

biocompatibility, biodegradability, low cytotoxicity, high chemical stability , good mechanical properties & cost effectiveness alongwith their chemical functionality, they can be easily modified to yield useful products such as:medical implantstissue engineeringdrug deliverywound healingbio sensors & diagnosticsmagnetic composites of nanocellulose for biomedical applications4

Wood adhesives - Researchers have a great interest in traditionally bio-based binders, such as starch , soy protein or renewable rubber, use of modified vegetable oils or lignin derivatives , and various cellulosic materials for application in the adhesive field.

Among these biopolymers, cellulose is the most abundant renewable biomaterial and its natural affinity for self-adhesion makes it a potential material in adhesion science. Reconstituted products, such as particleboard, oriented strand board (also known as flakeboard) and plywood panels, among others, appear as an alternative to solid wood, needs an improvement in the characteristics of the raw material. However, the quality of the final product depends mainly on adhesion technology. The most used adhesives in the production of panels of particleboard wood are the synthetic ones such as urea-formaldehyde, phenol-formaldehyde and melamine-formaldehyde.

The benefits of using nanocellulose as reinforcements in adhesives for the production of reconstituted wood panels include:

the possibility of altering the properties of adhesives, gain in mechanical and physical properties of panels and reduction in formaldehyde emissions by using synthetic adhesives.5Supercapacitors - Nanocellulose’s unique structure and remarkable properties, such as high specific modulus, excellent stability in most solvents, low toxicity, natural abundance, ecofriendly nature, low cost, easy availability and simple synthesis techniques render the nanocellulose as a promising candidate for the fabrication of green renewable energy storage devices. Specifically, development of nanocellulose materials for energy storage applications, particularly on supercapacitors.

A large number of hydrogen bonds exist intra and inter molecularly and yield different cellulosic structures. Nanocellulose offers a unique combination of properties including flexible surface chemistry, transparency, low thermal expansion, high elasticity, anisotropy and the ability to bind to other conductive materials, enabling extensive application in flexible energy-storage devices.6

Template for electronic components- In semiconductor manufacturing, a low-κ is a material with a small relative dielectric constant (κ, kappa) relative to silicon dioxide. Low-κ dielectric material implementation is one of several strategies used to allow continued scaling of microelectronic devices, colloquially referred to as extending Moore's law.

Nanocellulose’s outstanding dielectric properties, mechanical properties, thermal properties, transparency, and the rich hydroxy bonds endow them with great potential to be used as the matrix of high dielectric materials.

Besides, their inherent compatibility with organic polymer and easily processed modification also makes them excellent additives for dielectric substrates.7

batteries, electroactive polymers, 3D printing

continuous fibers and textiles, cosmetic

food coatings, paper products, cements

barrier/separation membranes, antimicrobial films

magnetically responsive material, oil and gas drilling

How does it get manufactured and is it easy or tough?

Cellulose nanocrystals (CNCs), usually produced by acid hydrolysis, consist of cylindrical, elongated, less flexible, and rod like nanoparticles with 4–70 nm in width, 100–6,000 nm in length, and 54–88% crystallinity index (Naz et al., 2019).

Nano fibrillated cellulose (CNF), commonly obtained by mechanical treatment, presents an entangled network structure with flexible, longer and wide nanofibers (20–100 nm in width and >10,000 nm in length), and lower crystallinity with respect to CNCs. The production of CNF from lignocellulosic biomass has most commonly performed through a range of chemical, mechanical, and enzymatic treatments, or a combination thereof, as recently described in detail elsewhere (Nechyporchuk et al., 2016; Osong et al., 2016).

Bacterial Cellulose also known as microbial nanocellulose, is considered as a promising and cost-effective natural nanomaterial for biomedical uses (Carvalho et al., 2019; Sharma and Bhardwaj, 2019). It consists of ultrafine, pure and ribbon-shaped nanofibers with 20–100 nm in diameter and micrometers lengths, which entangled to produce three-dimensional network as a hallmark. Such kind of nanocellulose is typically produced from bacteria, but its synthesis is seen extremely expensive because of the high costs of synthetic media

Insert section - Easy or tough to manufacture and is it getting easier

Is the market big & has anyone even used it yet ?

According to reports, the global nanocellulose market size was USD 291.53 million in 2019 and is projected to reach USD 1,053.09 million by 2027, a CAGR of 19.9% during the forecast period.8 Still very small but high growth.

So no the market is not very big right now but there are a few early emerging users such as 9:

CNCs (Cellulose Nanocrystals)

Anomera: (Montreal, Canada) - manufactures carboxylated cellulose nanocrystals (CNCs) through a unique and patented eco-friendly process from sustainably harvested Canadian forests. The material is sold under the trade name DextraCel.

DextraCel is claimed to have properties that exceed other cellulose nanomaterials on the market. Applications of DextraCel range from plastics and composites, paints and coatings, cosmetics, and cement, to life sciences and agriculture. Depending on the application, DextraCel can be used to improve the flexural and compressive strength and workabilityof concrete to make lighter, stronger, and longer-lasting materials; to modify rheology, provide barrier properties, and adjust the mechanical properties of paints and coatings; and in the design of intelligent release systems for drug delivery, among others

CelluForce: Also based in Montreal, Canada, CelluForce is focusing on the development and commercial production of cellulose nanocrystals. The company commercializes a family of CNC products under the brand name CelluForce NCC. CelluForce NCC exhibits useful properties such as self assembly, strength, a high surface area, and electromagnetic conductivity, among others. The product can serve as a biobased component in adhesives, cement, oil, plastics, nonwovens, electronics, personal and healthcare products, and food and beverages.

Melodea Ltd: Based in Rehovot, Israel, Melodea produces cellulose nanocrystals from wood pulp and paper production side streams. Melodea’s biobased CNC product is a lightweight, transparent, durable, and abrasive-resistant material that exhibits both self-assembly and barrier properties. It is highly compatible with water-based systems and is recyclable, compostable, and biodegradable.

Since Melodea’s product can serve as a high-performing oxygen, oil, and water vapor barrier, it is used for packaging and films as well as for paints and coatings, to improve their scratch and abrasion resistance. Melodea’s biobased solutions can also be applied to textile dyeing processes to increase efficiency, lower costs, and reduce waste.

CNFs (Cellulose Nanofibers)

Sweetwater Energy: (2009 New York State Energy Research and Development Authority funding and developed in collaboration with researchers at the Rochester Institute of Technology). Sweetwater Energy developed and refined a patented biomass pretreatment system with the backing of a wide group of private investors. The company began building their first Sweetwoods commercial-scale facility in 2019.

Sweetwater’s patented technology is called Sunburst. The main idea of the Sunburst technology is to deconstruct plant material such as wood into components that are efficient and clean enough to make products that traditionally rely on petroleum and other nonrenewable sources.

The company makes many forms of cellulose, including NFC, which is obtained via the Sunburst process as a loosely agglomerated microcrystalline cellulose that is further transformed into nanofibrillated cellulose.

Sunburst’s fabrication and operating costs are extremely low because the system is based on extrusion, a technology that has been the workhorse of countless industries for decades.

Fiberlean Technologies (UK): FiberLean Technologies is the leading global producer of Microfibrillated Cellulose (MFC). The product coming out of the FiberLean Technologies proprietary process is a MFC-mineral composite. The mineral plays an essential role in the transfer of mechanical energy, transforming regular pulp into MFC. This also allows the use of robust and reliable industrial equipment. In Papermaking the use of Microfibrillated Cellulose in full scale papermaking is now a reality. There are multiple possibilities to take advantage of the superior hydrogen bonding capability – “Natural strength”- of MFC. In Packaging products are tailored for several packaging applications. In Folding Box Board, MFC applied in the middle layer increases the bonding strength allowing for bulkier – less refined – fibers to be used to further separate the outer layers increasing the stiffness of the board at any given basis weight. For the outer layers of White Top Linerboard and Cartonboard, FiberLean MFC increases the opacity and strength of the top layer, whilst reducing porosity allowing for better coverage and basis weight reduction.

GranBio: (2011 -operations in Brazil and the USA) - GranBio has developed two patented BioPlus nanocellulose production technologies. They allow for the economical extraction of commercial scale nanocellulose from any biomass with adjustable particle size and composition. The low-cost product is aimed at use for large commodities and typically fiber-based markets such as the cardboard industry.

GranBio Tech is involved in the development of nanocellulose-enhanced products through collaborations with companies in various industries, such as high-barrier plastic packaging and lightweight automotive compounds, tires and rubber products, cosmetics, and cardboard.

BCs (Bacterial Nanocellulose)

Axcelon Biopolymers Corporation (ABC) (Canada) - company whose emphasis is on producing the BNC-based advanced wound care products Nanoderm and NanodermAg, with the latter having fibers that have silver incorporated into them. Both are made from bacterial nanocellulose as a microfibrillar biosynthetic cellulose film for a one-time single application wound care product that simulates fibrin to help promote faster wound healing.

The pore size created by the microfibrils and ribbons of Nanoderm’s paper-thin membrane trap platelets and initiate coagulation, bringing about both haemostasis and adherence to the wound surface. The greater absorptive capacity of the membrane and its porous nature allow for the dissipation of exudate while maintaining a moist wound interface. Nanoderm also acts as a regenerative tissue scaffold, and the tensile strength of the material allows it to remain in place for longer periods with little need for dressing change.

Few other Leading Companies Profiled in the Global Nanocellulose Market are:

Kruger, Inc. (Canada)

Borregard (Norway)

Nippon Paper Group (Japan)

Stora Enso (Finland)

Norske Skog ASA (Norway)

The University of Maine (U.S.)

Research Institutes of Sweden (RISE) (Sweden)

CelluComp (UK)

Conclusion:

Cellulose Nanomaterial is an emerging class of materials with a diverse set of application across a range of industry It is green in nature due to its primary source of origination being wood and for the same reason it is abundantly available. It is an extremely versatile material with superior mechanical properties owing to its large surface area and low density. There are multiple methods of extracting this material all of which are still expensive due to limited scale. It can be customized for various use cases. Some of the major use cases are foreseen in biomaterial, paper making, filtration methods among others. The overall market remains small (Current: $300Mn, 2027 (E) - $1-2Bn). U.S & Europe have a clear advantage in terms of both technology patents as well as manufacturing abilities. I could not find any India specific material although lot of papers on Scienedirect, Pubmed, Frontiersin etc. had references to India reviewers and writers.

See you next time until then keep cheering for Science

https://www.sciencedirect.com/science/article/pii/S2238785421007924

https://www.frontiersin.org/articles/10.3389/fchem.2020.00392/full

https://www.bbc.co.uk/bitesize/topics/znyycdm/articles/z2d2gdm#:~:text=Cellulose%20is%20a%20molecule%2C%20consisting,in%20the%20diet%20as%20fibre

https://www.researchgate.net/publication/309350498_Nanocellulose_and_its_Composites_for_Biomedical_Applications

https://www.scirp.org/pdf/OJPChem_2019101613575954.pdf

https://www.sciencedirect.com/science/article/pii/S2468217919300085

https://www.sciencedirect.com/science/article/pii/B9780128223505000047

https://www.fortunebusinessinsights.com/nanocellulose-market-104565

https://www.prescouter.com/2021/07/these-companies-are-revolutionizing-the-applications-of-nanocellulose-across-industries/